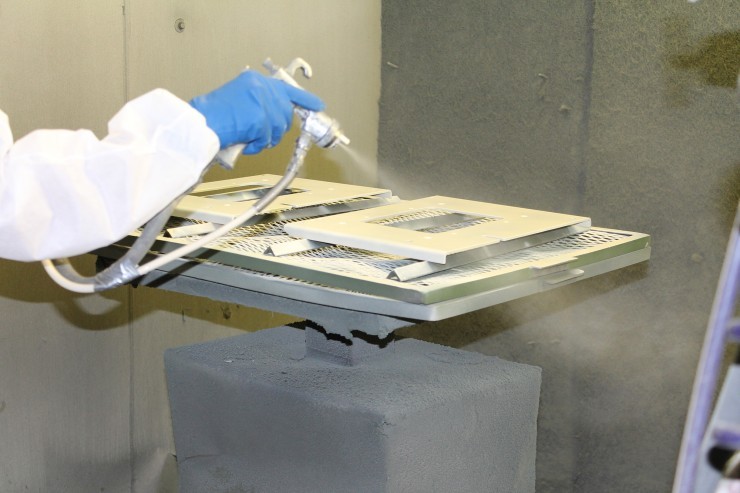

Rhinehart Finishing offers a wide array of industrial liquid spray painting for metal parts that not only meet industry standards, but also improve the performance of your equipment. Our 10 environmentally friendly paint booths are manned and ready to accommodate your industrial spray paint needs. With a maximum part size of 12′ x 3′ x 6′, we can handle just about anything you require.

Industries We Serve

- Military & Defense: We provide CARC coatings for tactical vehicles, weapon systems and components that are exposed to chemicals, abrasives and field abuse.

- Construction Equipment: Our rugged, chip-resistant coatings protect valuable equipment exposed to sand, impacts and UV radiation during everyday use.

- Automotive: Protecting automotive components from wear and corrosion becomes easier thanks to our extensive expertise.

- Aerospace: The finishes we deliver provide aerodynamic integrity, wear resistance and corrosion protection even in extreme altitudes and climate conditions.

- Manufacturing: We apply uniform finishes that meet the branding, durability and regulatory standards for a wide range of components.

Our extensive knowledge of industrial spray painting enables us to provide the most complete capabilities found anywhere. This means you will have proper protection from the elements, corrosion and contamination. Your equipment will last longer and perform in line with your expectations, if not exceed them. It’s no wonder that even the most demanding industries in the world turn to us to supply them with finishes that offer unsurpassed results.

Why Industrial Spray Painting Matters for Equipment Performance

With the right industrial spray painting capabilities, manufacturers can enjoy benefits including:

- Durability and Protection: Proper coatings shield equipment from UV radiation, corrosion, abrasion and chemical exposure, which is crucial for sectors such as defense, agriculture and manufacturing.

- Operational Integrity: With uniform coating thickness, tolerances and performance can be maintained for moving parts and assembled components.

- Aesthetic and Compliance Benefits: Spray-applied finishes ensure consistency and compliance with standards while also providing a polished, professional look to the finished product.

- Lifecycle Cost Savings: With high-quality industrial coatings, equipment operators can reduce their maintenance needs, extend the service life of the machinery and improve their overall ROI.

Liquid ‘Flatline’ Capabilities

Rhinehart Finishing utilizes a “flatline” system for industrial spray coatings. Although we specialize in CARC (Chemical Agent Resistant Coating), many commercial liquid finishes are available, as well. This solution is ideal for smaller parts and parts with intricate masking and configurations. Its design allows for a seamless flow through the entire process:

- Masking

- Painting

- Curing

- Detailing

- Assembly

- Packaging

- Transportation

Liquid ‘Overhead’ Capabilities

We utilize our “overhead” system for both liquid and powder options. This line, which has state-of-the-art automated controls, houses our seven-stage zinc phosphate pretreatment system, and is certifiable to TT-C-490, Type 1. Parts that require liquid coatings go through our manual prime and topcoat booths with the option of infrared cure between coats.

Chemical Agent Resistant Coating (CARC)

CARC spray paint applications differentiate themselves from other solutions with their resistance to corrosion and ability to deflect the absorption of chemical agents.

The United States Chemical Agent Resistant Coating is a system of pretreatments, primers and topcoats. Our team of specialists makes sure your CARC coatings meet all military requirements. See MIL-DTL-53039 to review scope, classification, colors (camouflage and non-camouflage) and government documents relating to this military specification. When you choose these custom industrial painting solutions, you can be certain your parts and products will be capable of withstanding some of the harshest environments and conditions possible.

Choosing the Right Spray System for Your Equipment

Rhinehart Finishing is your comprehensive partner for industrial painting capabilities, offering you a variety of systems to fit your project. Our industrial spray painting services include flatline systems, which are ideal for small, complex components that require detail masking, custom colors or intricate handling. On the other end of the spectrum, we also offer overhead spray painting systems that are best suited for larger parts or higher-volume production with consistent throughput and efficient pretreatment integration.

Whether you need automated capabilities to expedite rush jobs or manual processes to accommodate unique part geometries, you can count on Rhinehart Finishing to deliver the right services to meet your needs. Our experts can take a look at your project and suggest the techniques and methods that will yield the best results given your job’s size, geometry, volume and requirements.

Why Choose Rhinehart Finishing for Industrial Paint?

We stand apart from the other industrial painters because we’re dedicated to delivering the most complete and effective services. Our 100,000-square-foot facility is equipped with multiple spray lines for batch and continuous flow operations. With in-house mechanical cleaning, pretreatment, painting, masking, packaging and logistics support, we maintain tight standards of quality across every stage of your project.

Because we’re co-located with sister company Rhinehart Development, we can offer seamless coordination of fabrication and finishing. Our ISO 9001:2015 certification and TACOM approval for military-grade protective coatings also speak to our commitment to quality, repeatability and regulatory compliance.

Your Partners In Success

No matter what your business calls for, we can be your ultimate source for spray painting services. To put our full capabilities to work for your project, contact us today to ask any questions and receive your free quote.